Description

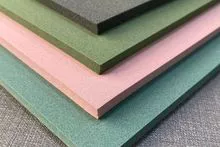

**Product Name**: Customized TPE Foam Solutions | Expert in Eco-Friendly High-Elastic Thermoplastic Foam Production

---

### **Core Advantages**

✅ **100% Recyclable Eco-Friendly Material**

Certified by RoHS/REACH, free from harmful substance emissions, meeting global environmental compliance standards.

✅ **Outstanding Performance**

- High resilience (compression set ≤15%)

- Excellent weather resistance (stable performance from -50℃ to 120℃)

- Slip-resistant and wear-resistant (Shore C hardness adjustable from 15~90)

- Shock absorption and noise reduction (energy absorption rate up to 85%+)

✅ **Customization Capabilities**

- Density range: 0.08g/cm³~0.50g/cm³

- Custom sizes/shapes (sheets/rolls/irregular parts)

- Surface textures/colors/flame retardant grades customization

- Composite structure development (laminated with EVA/PU/fabric, etc.)

---

### **Typical Applications**

◼ Automotive Industry: Seat cushioning layers, door seals, console shock absorbers

◼ Furniture Manufacturing: Sofa cushion cores, mattress support layers, anti-collision corners

◼ Medical Devices: Wheelchair seat pads, rehabilitation equipment grips, pressure sore prevention pads

◼ Sporting Goods: Yoga mats, fitness equipment handles, helmet liners

◼ Industrial Packaging: Shock-absorbing liners for precision instruments, anti-static transport pallets

---

### **Technical Specifications**

| Parameter | Standard Range | Testing Standard |

|-------------------|------------------------|---------------------|

| Density | 0.08-0.50g/cm³ | ISO 845 |

| Tensile Strength | 0.8-4.5 MPa | ASTM D412 |

| Tear Strength | 8-25 N/mm | ASTM D624 |

| Compression Set | ≤18% (22h/70℃) | ASTM D395 |

| Flame Retardant | HB/V0 Optional | UL94 |

---

### **Our Service Commitment**

🔹 Sample Development Support: 2-7 days rapid prototyping verification

🔹 Full Engineering Support: From material selection → mold design → mass production optimization

🔹 Flexible Order Quantities: Minimum trial order of 500 pieces

🔹 Quality Assurance: ISO 9001 certified, batch inspection reports included

🔹 Global Delivery: Supports sea/air/China-Europe freight train logistics options

---

### **About Us**

As a professional TPE foam manufacturer with 12 years of experience:

• 3 fully automated foam molding production lines, monthly capacity of 600 tons

• Team of 60+ engineers, holding 12 material formulation patents

• Serving 300+ global brand clients, exporting to 40+ countries

---

**Take Action Now**

📩 Click to inquire for a customized quotation

📦 Request free samples: Experience material performance, verify application scenarios

- Eco-friendly foam material

- TPE foam customization

- anti-fatigue floor mats

- automotive component supplier

- sustainable packaging solutions

Production Capacity:

5000

Delivery Timeframe:

Within 30 Days

Incoterms:

CIF - Cost, Insurance and Freight

EXW - Ex Works

FOB - Free on Board

Packaging Details:

Not informed

More about

WELLE Trade

0-10

Employees

200K - 500K

Sales volume (USD)

80%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Distributor / Wholesaler

Keywords

- EVA Foam

- PE Foam

- TPE Foam

- Polyethylene Foam

- Ethylene-Vinyl Acetate Foam

- Thermoplastic Elastomer Foam

- Made in China Ver Mais

Contact and location

-

Sean ********

-

+86 1********

-

ZhangJiaGang City / | China