Description

**【Product Overview】**

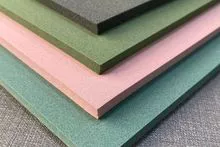

PE Foam (Polyethylene Foam) is a flexible, closed-cell foam material manufactured through high-pressure foaming technology. It combines lightweight properties with exceptional impact resistance, water and moisture resistance, and corrosion resistance. As an ideal cushioning and protective material, it is widely used in the packaging, sound insulation, thermal insulation, and shock absorption of electronics, precision instruments, industrial components, medical devices, and more.

---

**✔ Core Advantages: High-Cost-Effective Light Protection Specialist**

1. **Exceptional Performance**

- **Superior Cushioning**: High-resilience structure absorbs impact energy, effectively preventing product damage during transportation or storage, with seismic performance verified by ISTA/ASTM international standards.

- **Environmental Tolerance**: Waterproof, moisture-proof, and oil-resistant, it adapts to extreme temperature and humidity environments ranging from -40℃ to 80℃, maintaining long-term physical stability.

- **Lightweight & Eco-Friendly**: Density ranges from 20-200kg/m³ (customizable), reducing transportation costs; complies with RoHS/REACH standards and is 100% recyclable.

2. **High Customizability**

- Precision die-cutting/slitting/backing adhesive supported, offering custom shapes, rolls, sheets, and more to perfectly fit various product forms.

- Thickness options from 0.5mm-50mm, with customizable colors (black/white/gray/custom), density, and size adjustments available.

3. **Cross-Industry Adaptability**

▶ **Electronics**: Anti-static packaging for PCB boards, LCD screens, and instruments.

▶ **Industrial Packaging**: Cushioning pads for precision parts, edge guards for equipment.

▶ **Construction & Automotive**: Pipe insulation sleeves, base material for door seals.

▶ **Medical Logistics**: Insulation layers for cold chain boxes, shockproof liners for diagnostic equipment.

---

**⚙ Technical Specifications**

- **Certifications**: ISO 9001 quality system, SGS environmental test reports.

- **Standard Parameters**: Tensile strength ≥0.8MPa, compression strength at 25% deformation rate <70kPa.

- **Optional Upgrades**: Anti-static agents (surface resistance 10^6-10^9Ω), flame retardants (UL94-V0 rating).

---

**🎯 Why Choose Us?**

• **Direct Factory Supply**: 16 years as a professional manufacturer with automated production lines, ensuring consistent batch delivery.

• **Flexible Service Response**: 15-day rapid prototyping, OEM/ODM support, and 48-hour emergency order processing.

• **Global Logistics Support**: DDP/DAP services available, standard moisture-proof and pressure-resistant packaging, with free replenishment within the warranty period.

---

**📩 Get Your Exclusive Quotation Now!**

Click 【Inquiry Now】 to provide your application scenario and specifications. We will send technical parameter sheets and sample delivery arrangements within 2 hours.

---

**【Service Commitment】**

✅ Free sample performance verification ✅ One-on-one engineering solution design

✅ Bulk order tiered discounts ✅ 12-month extended quality guarantee

- Customized PE Foam

- Anti-Shock Packaging Material

- EPE Alternative

- Closed-Cell Polyethylene Gaskets

- Industrial Cushioning Liners

- Made in China

Production Capacity:

5000

Delivery Timeframe:

Within 30 Days

Incoterms:

CIF - Cost, Insurance and Freight

EXW - Ex Works

FOB - Free on Board

Packaging Details:

Not informed

More about

WELLE Trade

0-10

Employees

200K - 500K

Sales volume (USD)

80%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Distributor / Wholesaler

Keywords

- EVA Foam

- PE Foam

- TPE Foam

- Polyethylene Foam

- Ethylene-Vinyl Acetate Foam

- Thermoplastic Elastomer Foam

- Made in China Ver Mais

Contact and location

-

Sean ********

-

+86 1********

-

ZhangJiaGang City / | China