Description

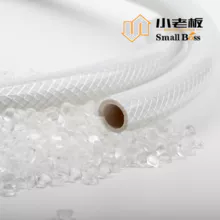

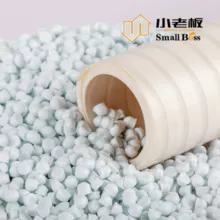

The PVC shoe particles launched by Tongxiang Xiaolaoban Special Plastic Products Co., Ltd. deeply integrate innovative technology and cutting-edge formulas to create high-performance raw material solutions for the shoemaking industry, fully meeting the dual needs of fashion and practicality. In terms of wearing experience, the shoe material made of the particles shows excellent softness and resilience, and the Shore hardness is controlled between 60-75A, which fits the curve of the foot, effectively buffers the impact of the ground when walking, and is not easy to cause fatigue after long-term wearing. At the same time, the particles have excellent air permeability and moisture permeability, which can avoid discomfort caused by hot feet and keep the shoes dry and comfortable, especially suitable for the production of daily shoes such as sports shoes and casual shoes. In terms of durability, the PVC shoe particles have been specially modified, and the wear resistance is significantly improved. Through the Akron wear test, the wear loss is as low as 0.15cm³/1.61km, and the soles made can withstand more than 100,000 bends without cracks, effectively extending the service life of the shoes. The product also has excellent anti-slip performance, with a friction coefficient of more than 0.6 on wet and slippery ground, providing users with safe and reliable walking protection. In addition, the particles are weather-resistant and still maintain good flexibility at -20℃ without brittle cracking; they are not easy to deform or stick even at 40℃, and can adapt to various complex climatic conditions. In terms of processing adaptability, PVC shoe particles have good plasticizing properties, and the melt index is stable at 1.8-2.2g/10min. They are suitable for various shoemaking processes such as injection molding, calendering, and extrusion, and the production efficiency is increased by more than 20%. At the same time, it supports personalized customization, and can adjust parameters such as color, hardness, and gloss according to customer needs to meet the design requirements of different styles of shoes. The products have passed a number of international safety standards certifications, such as EN71, ASTM, etc., to ensure that they are non-toxic and harmless, and provide consumers with healthy and environmentally friendly footwear products. The PVC shoe particles of Tongxiang Xiaolaoban Special Plastic Products Co., Ltd. have become the trusted choice of many well-known shoe companies with their outstanding performance and stable quality, helping to create comfortable, durable, and fashionable high-quality shoes.

- PVC shoe particles

- PVC particles

- PVC particles

- plasticized polyvinyl chloride particles

- PVC corrugated pipe materials

- PVC pipe materials

- PVC injection molding materials

- Alibaba

- Made in China

- PVC soles

Production Capacity:

1000000

Delivery Timeframe:

Within 30 Days

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

CIP - Carriage and Insurance Paid to

DDP - Delivered Duty Paid

DDU - Delivered Duty Unpaid

EXW - Ex Works

FCA - Free Carrier

FOB - Free on Board

Packaging Details:

25kgs per bag 1 ton per bag 20GP can load 21-26 tons 40FT can load 26 tons

More about

Tongxiang Small Boss Special Plastic Products Co.,ltd

200-500

Employees

10M - 50M

Sales volume (USD)

70%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Other

Keywords

- PVC granules

- PVC compounds

- PVC

- PVC material

- PVC for shoes

- PVC for fittings Ver Mais

Contact and location

-

Abby ********

-

+86 1********

-

Tongxiang / Zhejiang | China