Description

Multifunctional roll seam measuring instrument

Model: SPD-V020

Brief introduction:

In order to ensure the quality of the production slab, in order to ensure the quality of the production slab, the multi-function roller seam measuring instrument must be strictly controlled within a certain error range. Due to the relatively large equipment of the continuous casting machine and the relatively harsh production environment, it is difficult to measure the performance of the continuous casting machine manually, and many parameters are difficult to measure. For this reason, a system capable of simulating slab steel drawing and thus measuring the performance of individual parameters of the continuous casting machine is crucial. Multi-function roll seam measuring instrument equipment is in the case of simulating steel pulling, the use of various sensors to achieve the continuous casting machine between the roller seam value, the continuous casting section of the arc value, the roll rotation is good or bad, the size of the water spray pressure and other performance parameters to measure, so as to grasp the quality of the continuous casting machine in real time Convenient casting machine maintenance personnel to analyze the measurement results, can find the casting machine equipment problem area, these problems if not found and solved in time, will lead to continuous casting product quality degradation, casting process leakage of steel, Problems such as surface and internal cracks and centerline segregation occur

Roller seam meter measurement:

Roll seam value:

By measuring the spacing between a series of inner arc guide rollers and an outer arc guide roller on a continuous caster roller table, it can be used to set the correct roller gap spacing for each pair of guide rollers in a slab continuous caster.

External arc guide roller to arc:

By measuring the deviation between the position of the outer arc guide roller of the continuous casting machine and the adjacent two guide rollers and the original design position of the continuous casting machine, the arc condition of the outer arc guide roller can be obtained.

Guide roller rotation:

Measurements make it possible to know whether each guide roller can rotate freely.

Water spray pressure:

By measuring the operation of the water spray cooling system at different positions in the casting width direction of the casting machine, the operation of the water spray cooling system can be accurately determined whether the water spray at a certain point is normal.

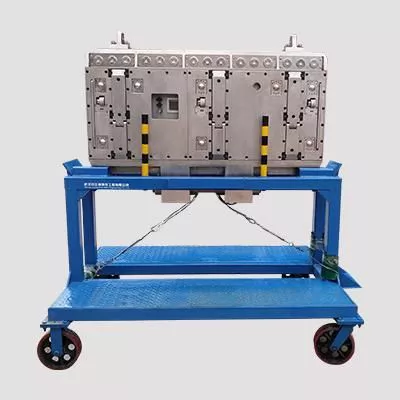

The main components of the roller seam instrument:

1. The roller seam gauge body used to measure the continuous casting fan section

2. Roller seam instrument and lead rod connection chain

3. Roller seam instrument storage rack chain

4. Battery charger: 24V 5A

5. Verify the equipment

6. Remote control

7. Laptop

8. Printer

9. Data communication cable

Technical parameters:

1. Roll seam measurement range: 210mm, 230mm (can be customized according to design needs)

2. Roll seam measurement accuracy: 0.01mm

3. Measurement range of arc: ±80°

4. Arc measurement accuracy: 0.01°

5. Spray measurement range: 0-10 grades

6. Spray measurement accuracy: ±1

7. Battery usage: > 3 times

- Multi-function roller seam instrument

Production Capacity:

Not informed

Delivery Timeframe:

Within 30 Days

Incoterms:

EXW - Ex Works

Packaging Details:

Not informed

More about

Wuhan CenterRise M&C Engineering CO., Ltd.

50-100

Employees

200K - 500K

Sales volume (USD)

10%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Thermocouple calibrator

- handheld roller seam instrument

- multi-function roller seam instrument

- leakage steel forecasting system

- large bag slag detection system

- converter lining thickness gauge Ver Mais

Contact and location

-

Floria ********

-

+86 1********

-

Wuhan / hubei | China