Description

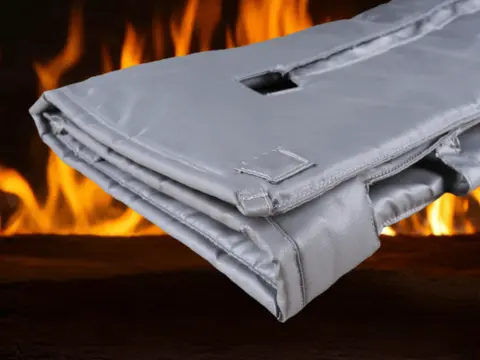

This insulating heat shield is designed for injection molding machine barrels and other high-temperature industrial equipment. It is made of multi-layer composite structure and high-performance insulation materials, which can significantly reduce heat loss, improve energy efficiency, and improve the safety of equipment operation and maintenance convenience. Its outer material has excellent weather resistance, water resistance and oil resistance, and can operate stably for a long time in complex environments such as humid, dusty, and oil-rich environments. The product is highly flexible and supports on-demand customization. It can be precisely cut and processed according to the shape, size and operating temperature of different equipment components to ensure a tight fit and lasting insulation effect. Whether it is a straight pipe structure or a complex curved surface component, the insulating cover can be quickly installed and safely disassembled. It is widely used in external thermal protection of equipment such as injection molding machines, vulcanizers, engines, flanges, storage tanks, heat exchangers and reaction vessels. The heat shield has a long service life, strong tear resistance and mechanical wear resistance, and can withstand repeated loading and unloading and long-term use without deformation or performance degradation. Its reusable structural design helps to reduce material waste and maintenance costs, and is an ideal choice for energy saving, environmental protection and operational safety. Product advantages: • Improved thermal efficiency: significantly reduce surface heat loss and energy consumption • Excellent protective performance: waterproof, oil-proof, anti-aging, high and low temperature resistance • Flexible customization: support thermal insulation coating with complex shapes and special specifications • Convenient operation: light and easy to assemble and disassemble, suitable for frequent maintenance of equipment • Safety protection: effectively reduce the temperature of the outer surface and reduce the risk of scalding Typical application industries: injection molding equipment, rubber vulcanization system, chemical storage and transportation, power system, precision thermal machinery, thermal management of manufacturing industry, energy industry and other fields. This special insulation cover for injection molding machine not only improves the efficiency of thermal energy utilization, but also enhances the safety of on-site operations. It is an important solution for energy-saving transformation and thermal protection upgrade of modern industrial equipment.

- Injection molding machine insulation cover

- industrial insulation cover

- high temperature insulation cover

- energy-saving insulation cover

- barrel insulation cover

- thermal protection cover

- oil-resistant and moisture-resistant cover

- removable insulation cover

- customized insulation layer

- vulcanizing machine insulation cover

Production Capacity:

10000

Delivery Timeframe:

Within 30 Days

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

DDU - Delivered Duty Unpaid

EXW - Ex Works

FOB - Free on Board

Packaging Details:

Customizable

More about

Shenzhen Petersburg Composite Materials Co., Ltd

200-500

Employees

1M - 2M

Sales volume (USD)

30%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- thermal insulation

- fiberglass

Contact and location

-

Lionel ********

-

+86 1********

-

Shenzhen / Guangzhou | China