Description

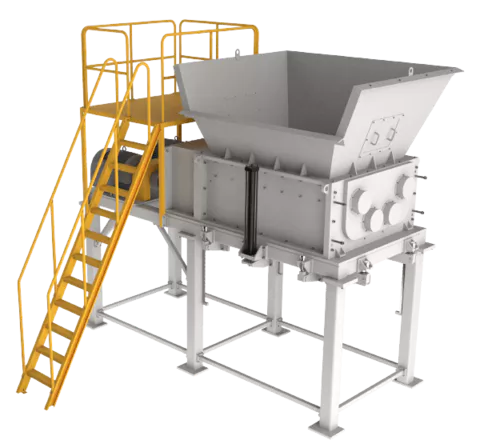

The four-axis crusher overcomes the traditional crusher and crusher to achieve the required specifications. Now with the broken mesh, the broken pieces can be directly broken to the desired finished product size. The four-axis crusher is suitable for the crushing of large-scale crushing objects such as wood, wire, wooden boards, aluminum cans, and rubber products.

10 characteristics:

■ Four groups of cutter shafts and hexagonal cutter shafts are designed to use multiple pieces of multi-claw cutters, which can be combined with the cutter shaft to make multi-angle changes, save labor and cutting force, and exhibit strong crushing ability.

■ The tool is made of special steel and hardened by heat treatment. It has a long service life and can be replaced in one piece and can be repaired by welding.

■ The electric motor directly connects the planetary gears and then the transmission structure of the gearbox transmission system makes it a powerful operation with low rotational speed and high torque, and it is easy to achieve the crushing effect. Low noise and less dust, improve the working environment.

■ The large-sized transmission gear is made of special steel, hardened by heat treatment, and the gear box is immersed in oil-type lubrication. The operation is smooth, low noise, large torque, long-time operation, and longer service life.

■ The screen hole adopts a "hexagonal" design, and the discharge is smoother. The one-piece net frame is driven by the gas (oil) pressure cylinder to raise and lower the grid, and then the synchronous gear row is matched to make the net frame lift more smoothly.

■ The two axes of the four-axis crusher have grabbing materials and the crushing function. The two axes are double-blade designs. There are three groups of ramming crushing lines when the four axes are rotated forward and reversed.

■ The crushing knife and the spacer are fitted with a half-moon type inner collar, a locking outer casing ring and a pressure plate, and the multiple points are loaded with a tight design method, so that the crushing knife can be closely combined with the spacer ring.

■ The crusher and cutter ring can be replaced without having to remove the cutter shaft, transmission gear, reducer and motor.

■ Can break the soft, hard, toughness and other substances. The gear box and the back side plate are designed with an isolated space. The crushing chamber can be cleaned with water without affecting the bearing and the oil seal.

■ When the current is overloaded, the electronic control automatically reverses. When it is reversed, the biaxial material is also broken and discharged, and then returned to normal rotation to continue crushing.

- Recycle

- Shredder

- Crusher

- wood

- wire

- wooden board

- aluminum cans

- rubber

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

CIF - Cost, Insurance and Freight

FOB - Free on Board

Packaging Details:

Not informed

More about

Recycle machine (crusher, shedder, seperator, screener)

10-50

Employees

2M - 10M

Sales volume (USD)

10%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Recycle

- Shredder

- Crusher

- screener

- hammer mill

- separator

- eddy current

- dust collector Ver Mais

Contact and location

-

Shun ********

-

+886 7********

-

Kaohsiung / | Taiwan