Description

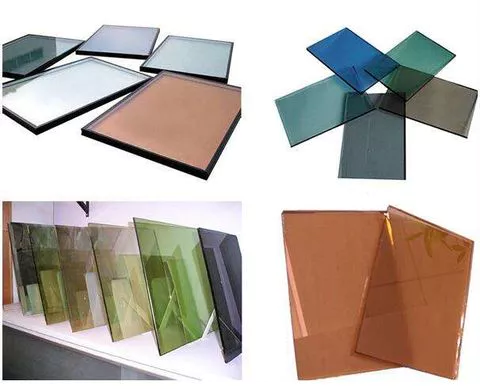

Coated reflective glass is obtained by fusing a metal oxide coating on the surface of float glass. According to the painting stage, it is divided into two types: online and offline. In-line reflective glass, coating is applied in the float glass manufacturing process. It is a chemical vapor deposition technique known for its durability, ease of cutting, and heat strengthening. Off-line reflective glass, on the other hand, is coated after the glass has finished leaving the production line. It is deposited by magnetron sputtering vacuum in a vacuum chamber with uniformity

Merit:

Mirror effect

- The exterior of the building is beautiful and generous

- Environmentally friendly and avoid light pollution

- Prevents solar and thermal radiation from penetrating the glass

- Superior durability and high scratch resistance

- Improves the hardness and corrosion resistance of the glass surface

Application:

- The exterior or interior of the building

- Doors, walls

- Furniture and fixtures

- Decoration, vehicles, mirror panels, optical instruments

Specification:

Thickness: 3 mm, 4 mm, 5 mm, 6 mm, 8 mm

Size: 3300x2134mm, 3300x2250mm, 1650x2140mm, or customized size.

- Float glass

- float tinted glass

- coated reflective glass

- tempered glass

- laminated glass

- embossed glass

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

Not informedPackaging Details:

Not informed

More about

Qingdao Joysun New Materials Co.,Ltd

100-200

Employees

Not informed

Not informed

Year

Established

Business type

- Industry / Manufacturer

Keywords

- glazier

- Safety glass

- Laminated glass

- Insulated glass

- Float glass

- Termpered glass

- Solar glass

- Reflective glass

- Patterned glass

- Mirror Ver Mais

Contact and location

-

Linda ********

-

+86 1********

-

Qingdao / Shandong province | China