Description

Introduction:

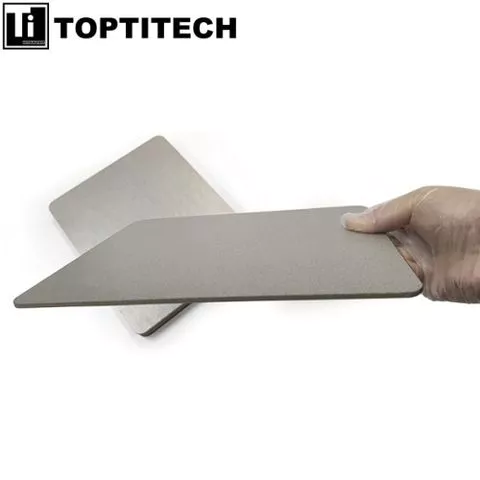

Porous titanium sheets are versatile materials used as gas diffusion layers (GDLs) in various industries. With their unique properties, these sheets enable efficient gas transfer, making them crucial components in fuel cells, electrolyzers, and other electrochemical applications.

Porous titanium sheets are typically produced through a process called powder metallurgy. It involves compacting titanium powder into a desired shape and sintering it at high temperatures. The sintering process creates interconnected pores, resulting in the desired porosity.

Specifications:

Filtration precision: 0.2um─100microns

Porosity: 30%─45%

Temperature resistance: 300 ℃(wet)

Thickness:0.5mm-50mm

Width: Max. 1500mm

Length: Max. 6000mm

Feature

Efficient Gas Distribution: The interconnected pore structure of porous titanium sheets allows for uniform gas distribution across the surface area, ensuring efficient gas diffusion and transport.

Enhanced Catalyst Utilization: The high surface area of porous titanium sheets allows for the deposition of catalyst materials, promoting efficient electrochemical reactions and maximizing catalyst utilization.

Low-Pressure Drop: The design of porous titanium sheets ensures minimal pressure drop across the gas diffusion layer, optimizing overall system performance.

Surface Area: Porous titanium sheets offer a high surface area, enhancing the gas diffusion process and providing better electrochemical performance.

Electrical Conductivity: These sheets exhibit good electrical conductivity, ensuring efficient current distribution within the electrochemical systems.

Water Management: Porous titanium sheets assist in managing water within the gas diffusion layer, preventing flooding and aiding in effective electrochemical reactions.

Application:

Fuel Cells: Porous titanium sheets serve as essential components in proton exchange membrane fuel cells (PEMFC) and solid oxide fuel cells (SOFC). They enable effective gas distribution, and water management, and provide electrical conductivity.

Electrolyzers: Porous titanium sheets are used in electrolyzers for hydrogen production. They facilitate efficient gas diffusion and enable water management, resulting in improved electrolysis performance.

Batteries: Porous titanium sheets find application in various types of batteries, including lithium-air batteries and redox flow batteries. They enhance gas diffusion, and electrolyte distribution, and provide structural support for the electrode materials.

Chemical and Petrochemical Industry: Porous titanium sheets play a vital role in catalytic reactors, gas separation units, and other chemical processes. They provide a high surface area for catalyst deposition and facilitate efficient gas transport.

- porous

- titanium

- sintering

- gas diffusion layer

Production Capacity:

100000

Delivery Timeframe:

Within 30 Days

Incoterms:

CIF - Cost, Insurance and Freight

EXW - Ex Works

FCA - Free Carrier

FOB - Free on Board

Packaging Details:

wooden box

More about

TOPTITECH(Baoji Yinggao Metal Materials Co., Ltd.)

10-50

Employees

1M - 2M

Sales volume (USD)

50%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Distributor / Wholesaler

Keywords

- SINTERED METAL FILTRATION CARTRIDGE ELEMENTS

Contact and location

-

TOPTITECH(Cherry ********

-

+86 1********

-

BAOJI / SHAANXI | China