Description

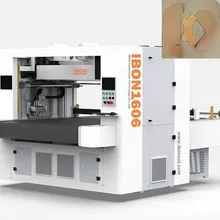

IB1625 CNC Oscillating Knife Cutter \ Car Mat \ Car Seat Cover Cutting Machine \ Digital Flatbed Cutter in Car Upholstery Industry

Product Description

1.The machine frame is quenched by high temperature,grinding and miling to ensure the long using life of the equipment;

2.2019 top-level operation system, simpler operating system, more powerful functions, data transmission is through USB. U disk,network cable interface etc, a variety of choices, comes with a powerfulsuper typesetting system;

3.Provide the service of operating software upgrades, promise free updates for lifelong;

4.Equipment electrical select the highest quality abroad (Japan Servo, Omron, etc)

Product Parameters

Equipment Features:

Specification Details

Working Area 1600 × 2500 mm

Applicable Materials PVC, Rubber, Foam, Sponge, Composite Material

Cutting Type Oscillate Knife

File Format PLT, DXF

Fixing Method Vacuum Absorption

Power Supply 220V-380V, 50Hz

Motor Japan Mitsubishi

Cutting Thickness 0.1 - 30mm (Depending on Material)

Cutting Head Single Head

Cutting Speed 60 - 2200 mm/s

Cutting Accuracy ±0.1 mm

Machine Type Flatbed

Features:

The body adopts open die design of die casting, strong rigidity and high stability.

The machine takes up little space and is most suitable for cutting multi-layer small slices, so it is convenient to use and save space.

The company independently developed intelligent nesting system, cutting system which are easy to operate, high utilization rate, time saving and material saving.

Intelligent double-head asynchronous cutting machine which can cutting, punching, with integrated tool holder make cutting efficient, accurate and simple.

The software is with function of design nesting and cutting integrated, which are convenient for operation, with fast nesting speed and high utilization rate.

The machine equipped with high frequency pneumatic knife can cut a variety of PU, microfiber, mesh cloth, PVC and other materials.

The platform adsorption adopts 16 pieces of vacuum adsorption zones, dynamic adsorption system.

The machine adopts imported servo motor, guide rail screw, pneumatic components and other accessories to ensure the accuracy, stability and durability of the machine.

Application:

Our digital leather cutting machine can cut shoe upper material, natural leather,artificial leather,synthetic leather, saddle leather, shoe

leather, PU leather,Genuine fabric, prepreg, neoprene, sole material, face leather, leather bag, leather gloves, leather shoes, car interior, sole

cutting, seat cover, printed leather, PU leather, mesh, wool slippers, sponge shoes, golf bags, fur, PVC, Foam,Acoustic panel, KT board, car stickers, rubber, sponge, carton, film, fiberglass, fabric, carbon fibercasual shoes and Various composite materials. deformation, no smoke, odor, safety, environmental protection and convenient maintenance. With a variety of tools and pens to meet the cutting needs of different materials, and provide a variety of personalized cutting services.

Specially developed for cutting small compents, it can cut multiple layers of material (cutting thickness: 12-18mm). Equipped with dual asynchronous heads and an intelligent nesting system, it maximizes material utilization. The combination of casting technology and a high-precision screw drive system ensures high-precision cutting.

Applied in the footwear and apparel accessories industries: digital cutting and punching of flexible materials such as TPU/PU, gaskets, leather, rubber, counter, mesh fabric, sublimation printed fabric, midsole fabric, gloves, hats, and more.

If use our digital cnc leather cutting machine:

1. knife cutting machine uses an automatic feeding work platform and is equipped with a super discharge system, which saves time for manual typesetting, improves work efficiency, and saves 10% of materials;

2. The traditional manual cutting efficiency and precision can no longer meet the needs of the market. The cutting accuracy and efficiency of the automatic digital blade cutting machine can meet the needs of different industries;

3. automatic blade cutting machine adopts the advanced oscillation knife cutting machine technology, the edge of the cut fabric will not appear yellow and scorched, there is no odor at the processing site, and the cutting edge is smooth;

4. High degree of intelligence, combining automatic feeding, automatic nesting and automatic cutting system, which reduces production costs and improves production efficiency.

After Sales Service

1. 12 months warranty for the whole machine. Technology support all life time.

2. We will supply the machine with training video and user's manual in English for installing, operation, maintenance and trouble-shooting, and shall give technical guide by e-mail, telephone, video online and so on, when you meet some problems of installation, using or adjusting.

3. You can come to our factory for training. We will offer professional guide. Direct and effective face-to-face training. Here we have assembled equipments all sorts of tools and testing facility,we will also provide accomadation during training period.

4. We can provide door to door service if needed.

Packing Process for Machines:

Machine Cleaning:

Thoroughly clean the machine to ensure it is free of dust and debris.

Protective Wrapping:

Wrap all machine parts with bubble film and plastic film. Place anti-friction and collision pads at corners. Arrange small parts on the machine bed to save space.

Transport and Packing:

Trailer the machine to the packing area. Use a forklift to place it into a fumigated wooden case. Secure the machine with sticks on the bottom plywood. Customize the wood case with grooves to fit the machine perfectly, preventing sliding. Reinforce the case with steel wires to avoid deformation. Wrap the case with waterproof cloth to protect against moisture and rust.

FAQ:

1. Can it be used for the fabric industry?

Yes, our digital cutting machines can be widely used in fabric, cloth, pu leather and other flexible material industry.

2. What's the mas thickness of ur pneumatic cutting tool can cut?

Our digital cutting table can be installed with the pneumatic cutting tool, and this tool can cut up to 70 mm;

3. The work you wanna handle with this digital cutting machine(Engraving ? Cutting ? Or others?)

The digital cutting machines can do the job of cutting, creasing and marking.

4. Do you have the manual of fabric cutting machines?

Yes,we can provide manual,CD software and video to help you operate the machine expertly.

5. If we do not know how to use the cnc cutting machine,can you teach us?

Yes ,of course. We can offer you free training, and engineers available to service machinery training overseas if you would like to offer them business expenditure.

6.How about your guarantee period for the digital cutting table?

Twelve months for the whole machine and 3 months for consumables including laser tube, lens and mirrors.

- Car Seat Cover Cutting Machine

- car interior Cutting Machine

- flexible materials Cutting Machine

Production Capacity:

30

Delivery Timeframe:

Within 60 Days

Incoterms:

CIF - Cost, Insurance and Freight

EXW - Ex Works

FOB - Free on Board

Packaging Details:

Wooden Case

More about

DongGuan IBON Automotion Techology Co.,Ltd

100-200

Employees

500K - 1M

Sales volume (USD)

90%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- knife cutting machine

- shoe marking machine

- shoe line drawing machine

Contact and location

-

Sally ********

-

+86 1********

-

Dongguan City / Houjie Town | China