Description

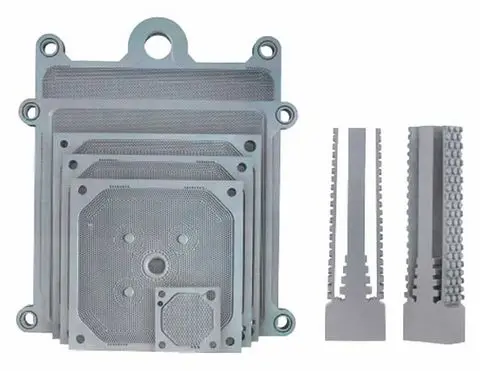

The filter plate is the core component of a filter press. It is primarily used for solid-liquid separation and is widely used in the chemical, mining, environmental protection, and food industries. Made of polypropylene, reinforced polypropylene, or metal, the filter plates are corrosion-resistant, withstand high pressures (0.6-2.0 MPa), and high temperatures (≤120°C). During operation, the filter press's multiple filter plates are tightly arranged by a hydraulic system to form a sealed filter chamber. Driven by pressure, the slurry enters through the feed channel, permeates the filter cloth, and exits through the plate's guide holes, trapping solid particles and forming a filter cake. The filter plate's structural design (such as groove depth and flow channel distribution) directly impacts filtration efficiency, cake solids content, and equipment processing capacity. High-end models are equipped with reinforced polypropylene filter plates, featuring a precise flow channel layout achieved through a molding process. An automated control system enables rapid unloading, backwashing, and remote monitoring, significantly improving the stability and cost-effectiveness of industrial continuous filtration operations.

- filter plate

- polypropylene filter plate

- pp filter plate

- stainless steel filter plate

- filter press

Production Capacity:

Not informed

Delivery Timeframe:

Within 30 Days

Incoterms:

Not informedPackaging Details:

Not informed

More about

Kerte Environment Co., Ltd

200-500

Employees

10M - 50M

Sales volume (USD)

50%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- filter press

- filter plate

- filter cloth

- pump

Contact and location

-

Wang ********

-

+86 1********

-

Hengshui / Hebei | China