Description

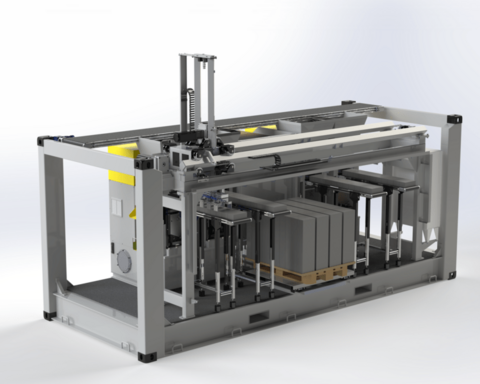

TITAN MOBIPRESS — mobile brick & block making plant

TITAN MOBIPRESS is a containerised, rapidly deployable plant for on-site production of bricks, blocks, tiles, and briquettes. Built around Titan’s compact high-pressure press technology, MOBIPRESS brings a full mini-factory to remote or space-constrained locations—assemble, produce, and ship from the job site instead of hauling materials to distant plants. It’s a practical way to launch new capacity fast, respond to rebuild needs, or validate markets before investing in a permanent facility.

What it includes (typical module)

High-pressure hydraulic press (Titan 80-series or equivalent, mix/format-dependent)

Dosing & intensive mixing with controlled moisture and pigments

Material flow via conveyors and hoppers with recipe control

Green-product handling for gentle ejection, transfer, and grouping

Power & control: HPU, control cabinet, HMI; remote diagnostics

Containerised frames for rapid setup, safe transport, and easy winterisation

What it makes

Facing bricks, blocks, thin bricks/tiles, and pavers with crisp edges and reliable dimensional accuracy

Briquettes from mineral fines, quarry dust, or process by-products for waste valorisation

Hyperpressed products that cure without firing, enabling clinker-grade aesthetics with far lower energy input

Why plants choose MOBIPRESS

Truly mobile: ships as standard modules; field-assembled with minimal civil works

Off-grid capable: generator-ready for sites without stable power

Use local materials: reduce trucking by sourcing aggregates and fines on site

Fast time-to-value: commission quickly, prove demand, then scale or relocate

Consistent quality: high-pressure forming + intensive mixing deliver dense, uniform products

Flexible portfolio: run bricks, blocks, tiles, or briquettes with recipe-based changeovers

Built for remote & disaster zones

Deploy where building materials are scarce: the containerised factory format is designed to be sent directly into hard-to-access regions to restore local production capacity quickly.

Mobile Crisis Construction

Rubble-to-rebuild workflow (with add-on crushing/screening): pair MOBIPRESS with site crushers/sieves to process debris and local spoil into graded feedstock, then press interlocking blocks or bricks for rapid shelters and critical-infrastructure rebuilds—minimising import logistics.

Mobile Crisis Construction

Speed + reliability: on-site production accelerates early-phase reconstruction and reduces supply-chain risk versus hauling finished masonry into crisis areas.

Mobile Crisis Construction

Community-centric setup: modular equipment and recipe libraries support quick operator training and stable, repeatable output in tough conditions.

Mobile Crisis Construction

“Anywhere” footprint: the mission behind containerised mobile block factories is to deliver shelter where it’s needed, even in disaster zones with damaged infrastructure.

Mobile Crisis Construction

Typical production flow

Material dosing & mixing → moisture-controlled, pigment/cement additions

High-pressure forming → precise compaction for strength and surface quality

Green handling → careful ejection and grouping to protect edges

Curing & storage → ambient or accelerated curing (product-dependent), then packing

Options

Alternative presses and toolsets for different formats

Add-on crushing/screening packages for debris and local raw materials

Weather protection kits, dust control, and cold-climate packages

Extended remote support, training, and spare parts kits

Ideal applications

Remote regions and off-grid sites

Disaster-response / recovery hubs coordinated by NGOs, municipalities, or EPCs

Pilot plants and market validation prior to fixed CAPEX

Mining & industrial sites converting ore sievings / fines into saleable bricks or briquettes

At a glance (quick specs)

Plant type: containerised mobile brick/block/briquette line

Core process: high-pressure hydraulic pressing with intensive mixing

Power: grid or generator (off-grid operation supported)

Setup: rapid assembly; modular scaling with additional press modules

Controls: HMI with recipe library and remote diagnostics

- rubble recycling disaster zones

- brick machine

- block machine

- block making machine

- tile machine

- tile making machine

- press for interlocking bricks

Production Capacity:

20

Delivery Timeframe:

Within 60 Days

Incoterms:

Not informedPackaging Details:

Not informed

More about

Titan Machinery

50-100

Employees

2M - 10M

Sales volume (USD)

60%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Representative / Agent

- Business Service

Keywords

- brick machine

- brick making machine

- block machine

- block making machine

- tile machine

- tile making machine

- concrete brick machine

- concrete block machine Ver Mais

Contact and location

-

Roman ********

-

+48 50********

-

Gdańsk / | Poland