Description

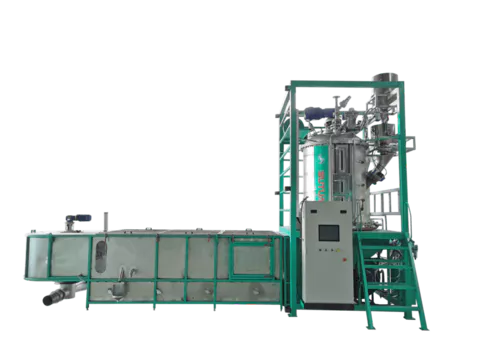

The EPS pre-expander machine adopts programmable control with touch screen control to achieve automatic feeding, automatic electrical calculation, automatic control of barrel temperature and air pressure, automatic inductive material measurement and other functions. The high precision measuring system ensures accurate feeding. The barrel body is made of stainless steel plate, with a tight structure, using high quality closed constant pressure foaming technology and efficient thermal efficiency design, compared with continuous foaming machine energy savings of about 65%. reliability and long service life. The vibration sensor imported from South Korea is used to control the volume of the foaming material and to make the density of the luminous beads consistent. The automatic discharge uses a full aluminium alloy disc finishing bottom discharge method, which enhances the speed of the discharge and makes it very clean. The drying bed system is made of 304 stainless steel, which has very good corrosion and high temperature resistance.

- eps pre-expander

- eps pre expander

- eps batch pre-expander

- eps foamer

- eps foam making machine

- eps beads making machine

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

EXW - Ex Works

FOB - Free on Board

Packaging Details:

Not informed

More about

Hangzhou Sutuan Machinery Co., Ltd.

100-200

Employees

10M - 50M

Sales volume (USD)

30%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- eps shape moulding machine

- eps block moulding machine

- eps shape molding machine

- eps pre-expander

Contact and location

-

Ming ********

-

+86 1********

-

Hangzhou / | China