Description

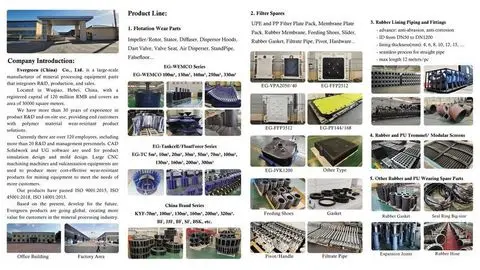

As a manufacturer of mining and metallurgical equipment and accessories integrating R&D, production, and sales, we possess a comprehensive suite of large-scale production equipment, including advanced UG product design, CNC machining centers, internal mixers, open mixers, and φ3.5m*13m autoclaves. We also maintain a well-equipped laboratory. Since 2015, we have been developing steel-rubber composite pipes to reduce production costs and provide higher-quality products and services for companies involved in mineral processing, thermal power generation, and chemical engineering. We have significantly improved upon similar products on the market in terms of material selection and design. At the beginning of 2017, we began actively promoting this product both domestically and internationally. As a manufacturer of mining and metallurgical equipment and spare parts integrating R&D, production and sales, we are equipped with a series of large-scale production facilities such as advanced UG product design, CNC machining centers, internal mixers, open mills, and φ3.5m*13m vulcanizing tanks, as well as a fully equipped laboratory. Since 2015, our company has been engaged in the research and development of steel-rubber composite pipe products, aiming to reduce production costs and provide better product services for enterprises in the mineral processing, thermal power, chemical and other industries. We have made significant optimizations and improvements to similar products on the market in terms of material selection and design. At the beginning of 2017, our company started to vigorously promote this product both at home and abroad. With the current equipment and staffing of our company, we can produce 50 kilometers of DN100-DN400 steel-rubber composite pipes per year, and 30 kilometers of DN500-DN800 steel-rubber composite pipes. As a supplier of equipment for large-scale mines and mining companies both domestically and internationally, quality is crucial to ensuring the smooth implementation of projects. Since its establishment, our company has prioritized quality control, strictly implementing the ISO9001 quality management system. We conduct rigorous assessments and inspections of raw materials, semi-finished products, and finished products, and have developed an ITP testing plan. Through rigorous product quality control and management, we continuously enhance our brand influence. Through years of continuous improvement, we have established a comprehensive quality management and control system, rigorously monitoring and controlling every aspect of our product processes, including raw material procurement, processing, shipping, quality statistics, performance testing, and overall quality management. The company has established a quality control structure in which the marketing department, production department, R&D center, sales department, after-sales department and quality control department jointly control product quality. The company has set up a special quality control department to oversee the company's overall internal control and quality system construction. Production inspection is carried out by the inspection center. The sales department and after-sales department jointly oversee the entire production implementation process to ensure timely feedback from customers on product quality. As a large-scale mining company and a supplier of domestic and foreign mining equipment, quality is the key to ensuring the smooth implementation of projects. Since its establishment, our company has always regarded quality control as one of the focuses of our work. We strictly implement the ISO9001 quality management system, conduct strict assessment and inspection of raw materials, semi-finished products and finished products, and formulate ITP inspection and test plans. Through strict product quality control and management, the company continuously enhances its brand influence. Through years of continuous improvement, the company has established a complete quality management and control system, strictly monitoring and controlling all aspects of the product, including raw material procurement, processing, delivery, quality statistics, performance inspection, and the quality system. The company has established a quality control framework in which multiple departments, including the Marketing Department, production department, R&D center, sales department, after-sales department and quality control department, jointly control product quality. center. Throughout the implementation process of production, the sales department The flotation machine spare parts series was developed and produced by a team led by Mr. Wang Naiwang, Chairman of Agri (China) Co., Ltd. in 2000. Initially, the team focused on producing flotation machine stators and rotors designed by the Beijing Research Institute of Mining and Metallurgy, including various models such as SF, KYF, XCF, and JJF. The largest KYF flotation machine stator rotors were 160m³ and 320m³, respectively. These stators and rotors primarily served the Wushan Mine, with which they continue to work to date. In 2009, the team partnered with Alfred Smith to produce flotation machine stators and rotors for WEMCO and DORR. These products serve iron ore, potash, and molybdenum concentrators, with the largest sized stator rotors at that time reaching 160m³ for WEMCO and DORR. These stators and rotors continue to serve iron ore concentrators to date. By 2013, we had achieved the most comprehensive range of models and largest product sizes in the domestic flotation cell stator and rotor industry. With the establishment of Agri (China) Co., Ltd. in 2015, our flotation cell stator and rotor business rapidly expanded. In 2016, we began developing the stator, rotor, inverted cone, vertical cylinder, guide tube, cone valve, and other accessories for the WEMCO-330m³ flotation cell, the largest flotation cell in China. Trials began at a domestic copper mine in 2018, and mass production of this stator and rotor model began in 2019. By 2021, all 16 WEMCO-330m³ stators at the customer's copper mine would have been replaced. In 2020, we began production of TC-type stator rotors, including the TC-20, TC-50, TC-100, TC-200, and TC-300. To date, our flotation cell stator and rotor production continues to expand in both model and volume. The flotation machine spare parts series was developed and produced by a team led by Mr. Wang Naiwang, the chairman of Evergreen (China) Co., Ltd. in 2000. Initially, it mainly produced flotation machine stators and rotors designed by Beijing Research Institute of Mining & Metallurgy, including various models such as SF, KYF, XCF, and JJF stators and rotors. The KYF type flotation machine stator and rotor with the maximum dimensions of 160m³ and 320m³ mainly serve Wushan Mine and have been cooperating with Wushan Mine up to now. Since 2009, the team has been collaborating with FLSmidth to produce the stator and rotor of WEMCO and DORR flotation machines. The products are used in iron ore, potash, molybdenum ore processing plants, etc. At that time, the largest size was the 160m³ stator and rotor of WEMCO and DORR flotation machines. Up to now, the team has been cooperating with iron ore processing plants. By 2013, it had basically achieved the production of the most complete models and the largest product sizes in the domestic flotation machine stator and rotor industry. In 2015, Evergreen (China) Co., Ltd. was established, and the business of stator and rotor for flotation machines developed rapidly. In 2016, the development of WEMCO-330m³ flotation components such as the stator, rotor, inverted cone, split tube collar, draft tube and dart valve began. This model is the largest flotation machine in China. The trial use of this model of stator and rotor began in the domestic customer's copper mine plant in 2018. Mass production of this model started in 2019. By 2021, all 16 sets of WEMCO-330m³ stator and rotors in the customer's copper mine plant had been replaced. The production of TC-type stators and rotors began in As a mining and metallurgical equipment and accessories manufacturer integrating R&D, production and sales, Aige Rui (China) Co., Ltd. has a series of testing and inspection equipment such as advanced UG product design, CNC machining center, 4000mm*4000mm*6000T flat vulcanizing press, etc. Since 2016, it has started to develop Metso VPA20 filter plates, diaphragm plates and rubber diaphragm products with the aim of localizing such products, reducing production costs for mineral processing enterprises and providing better quality products and services. Our company has optimized and improved the original filter plate series in terms of material selection and design. After careful research and design by our senior technical engineers, this product was put into operation in 2017 at the Jianshan Filtration Operations Area of TISCO Group. To date, it has been in operation for nearly five years and has performed well. At the beginning of 2018, our company began to vigorously promote this product domestically and internationally, and has established long-term cooperative relationships with many mining companies, including TISCO Group, Ansteel Group, Zhaoyuan Gold, and CITIC Pacific Fu'ao Mining. By the end of 2022, our company had successfully developed filter plates and rubber diaphragms for Metso Outotec's VPA15 series, VPA20 series, FFP2512, and FFP3512 filter presses. Evergreen (China) Co., LTD. as a manufacturer of mining and metallurgical equipment and spare parts integrating R&D, production and sales, is equipped with advanced UG product design, CNC machining centers, 4000mm*4000mm*6000T flat vulcanizing machines and a series of other testing and inspection equipment. Since 2016, we have been engaged in the research and development of Metso VPA20 filter plates, membrane plates and rubber diaphragms, with the aim of localizing such products to reduce production costs for mineral processing enterprises and provide them with better product services. Our company has optimized and improved the original factory filter plate series products in terms of material selection and design. After careful research and design by our senior technical engineers, they were put into use in the Jianshan Filtration operation area of Taiyuan Iron and Steel Group in 2017. Up to now, they have been running for nearly five years and have performed well. At the beginning of 2018, our company began to vigorously promote this product both at home and abroad. At present, we have established long-term cooperative relationships with many mining enterprises such as Taiyuan Iron & Steel Group, Ansteel Group, Zhaoyuan Gold, and CITIC Pacific Australia Mine. By the end of 2022, our company had successfully developed filter plates and rubber diaphragms for Metso Outotec VPA15 series, VPA20 series, FFP2512, and FFP3512.

- Flotation machine stator rotor

- filter press filter plate

- filter press accessories

- flotation machine accessories

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

Not informedPackaging Details:

Not informed

More about

Evergreen (China) Co., Ltd.

100-200

Employees

1

Sales volume (USD)

70%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Flotation machine rotor

- flotation machine stator

- filter press filter plate

- filter press diaphragm

- distributor

Contact and location

-

Lisa ********

-

+86 1********

-

Dezhou / Shandong | China