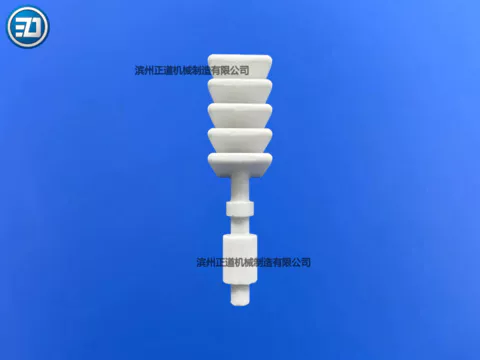

Description

Product Usage:

Complex cavity forming inside aluminum castings.

Peculiarity:

1. Compared with the ring-shaped piston salt core, the special-shaped salt core can be made into any shape of salt core products through the optimization and upgrading of the process; 2. The strength of special-shaped salt core is higher than that of ordinary piston salt core;

3. Compared with sand core and ceramic core, it is easier to clean and has a better surface finish; 4. It can be widely used in cavity forming of aluminum alloy products.

(1) The new salt core is applied to the internal cavity of all lightweight castings

Advantages: Most lightweight castings currently use resin sand cores to form complex internal cavities. When the sand core is cleaned in the later stage, there will be local sand sticking, which makes it difficult to clean the internal cavity, which is an inevitable technical problem.

The development of a new type of salt core can easily solve the problem of difficult sand removal of castings.

The salt is soluble in water and only needs to be rinsed with water to meet the technical requirements for removing the internal core. The use of salt cores in the field of pistons is already a very mature process. The new salt core is an extension of piston salt core technology.

(2) The new salt core is used in the difficult-to-process parts of injection molding products

Advantages: For the products that are difficult to process in the later stage of injection molding, the parts that need to be processed in the later stage of direct molding with new salt cores can be selected; The salt core is placed into the mold for injection molding before injection molding. It eliminates the technical difficulties of difficult processing in the later stage.

- Salt cores

- foundry consumables

Production Capacity:

99999

Delivery Timeframe:

Immediate

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

CIP - Carriage and Insurance Paid to

CPT - Carriage Paid to

DAF - Delivered At Frontier

DDP - Delivered Duty Paid

DDU - Delivered Duty Unpaid

DEQ - Delivered Ex Quay

DES - Delivered Ex Ship

EXW - Ex Works

FAS - Free Along Ship

FCA - Free Carrier

FOB - Free on Board

Packaging Details:

Not informed

More about

Binzhou Zhengdao Mechanical Manufacturing Co., Ltd.

200-500

Employees

1

Sales volume (USD)

70%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Distributor / Wholesaler

Keywords

- Salt cores

- wear-resistant liners

- ductile iron pistons

- high-silicon molybdenum ductile iron

- high-nickel ductile iron.

Contact and location

-

Nick ********

-

+86 54********

-

Binzhou / Shandong | China